The Future Beyond Automation

Dr. Atsushi Shibai, who studied at the National Institute of Technology (KOSEN) before coming to BDR to pursue automation research, introduced me to a fellow KOSEN graduate Dr. Nobuyuki Tanaka. I had met Dr. Tanaka on a different occasion when he had shown me a device to measure “wettability”. As soon as I arrived at Dr. Tanaka’s office this time, he said to me, “Let’s go to the microfabrication cleanroom.”

A microfabrication cleanroom for biology?

(Tanaka▷) Please change into the gown before entering. We are trying to prevent dust from entering the room, which houses equipment and tools for microfabrication and precise measurement—the most obvious equipment being microscopes, specifically, digital microscopes used to measure surface topography. And this atomic force microscope is used to observe protein structures or biomolecular dynamics.

(Yakushiji▷) What is this instrument that looks like a vacuum chamber?

That is a lithography system. It creates patterns on the surface of materials by exposing them to light and electron beams. Light has a diffraction limit, and this means that it cannot produce objects smaller than its wavelength, so we generally use electron beams to make any object smaller than one micrometer.

What kind of small objects are you making?

We are making devices that allow us to control the placement of cells, such as confining a single cell, lining cells up in a row or creating a cell sheet.

So in this room, you build experimental apparatuses and verify that they have been properly fabricated using precision measurement devices.

Yes. But the scale is extremely small. So factors like dust, temperature, and humidity become extremely important and is why we use a cleanroom. There is also a camera and a sensor for sound.

I can understand why you have a camera installed, but why a sound sensor?

We are not in the room 24 hours a day, and we need a way to know when the alarm sounds due to errors or troubles with one of the equipment.

I see.

Let’s move to the next room.

It’s like something made in a small-scale factory in Osaka!

Research automation is also another topic of research in the lab, and in this room we have a robots for experimental automation.

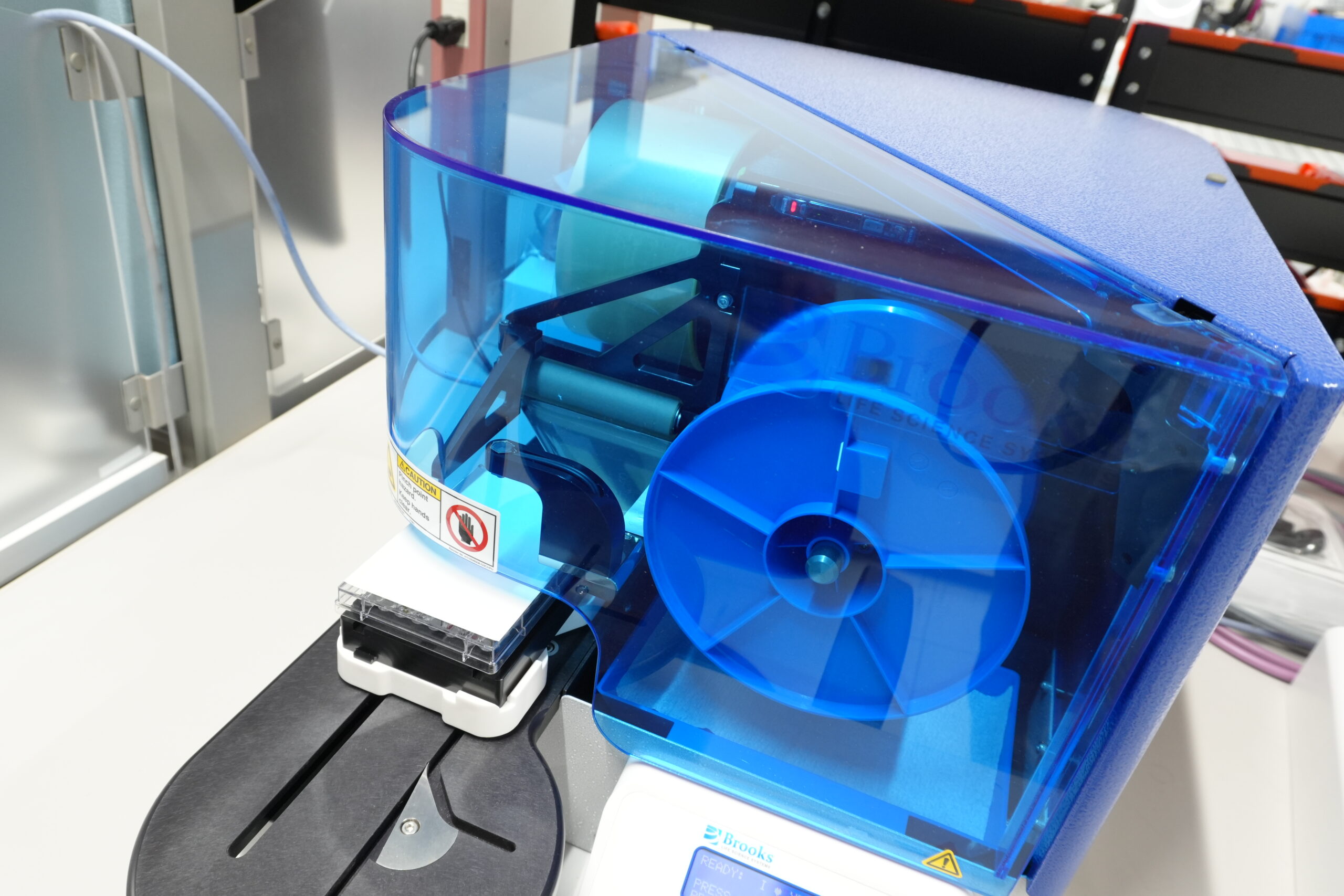

This is a ‘sealer’ robot that sticks adhesive film on top of 96-well plates to seal them up. And this is a robot that removes that adhesive film, also known as a ‘peeler.’ Next to that is an automated centrifuge. When you place the plate here, it is whisked into the machine and then it is automatically centrifuged.

These robots each have their own specific functions, so will another robot be moving the plate between these robots?

Yes. We are currently doing some preparations to link the different robots together. We have a student from Osaka University, who is a strong programmer, helping us to develop control software. The plan is to control the robots through digital commands and we are currently devising a digital communication protocol that will allow us to do this.

I did not know that there were robots for sticking and removing adhesive films. I am especially curious about how they remove the film. If it is not done right, I imagine that it will be like when opening a bag of potato chips goes wrong and the bag tears.

It’s genius actually. This [robot] has a roll of adhesive tape-like film that is used to remove the sealed film. When the sealed plate is inserted into the robot, the adhesive tape-like film is adhered to the top of the surface of the film you want to remove. The robot then peels the film off the plate by rolling the film horizontally away from the plate.

Smart. Kind of like a packing-tape system.

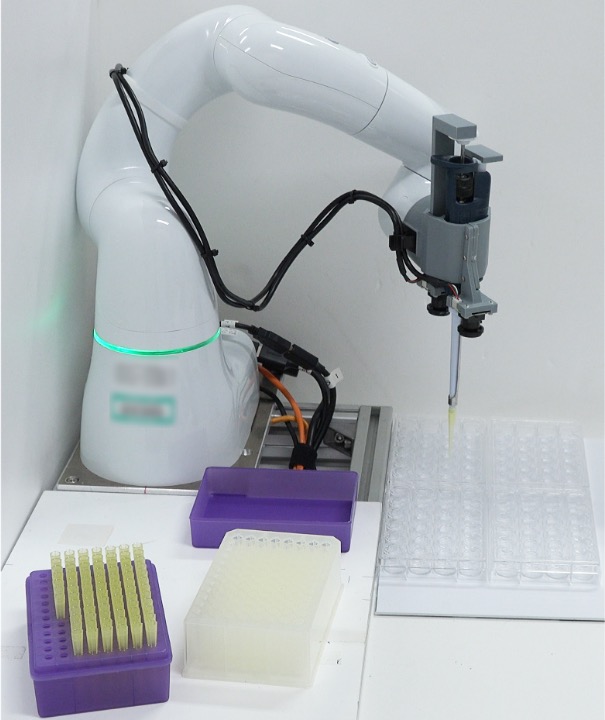

These robots do not have a typical robotic form and are specialized for a specific function or role, but there are of course robots with robot-like arms.

This is cute!

It is, isn’t it? This robot also works very energetically. It’s not only cute, but I think this robotic arm is optimally designed for mass production. The manufacturer of this robot is likely targeting its use in factories where several hundred units are installed for use.

Like car manufacturers?

In Japan, it would be the manufacturing industry. However, in the Americas and Europe, the so-called mega pharmas have already been incorporating experimental automation for quite some time. Thus, this has led to advances in development of automated devices and robots for the life sciences. In Japan, there is what is referred to as a “drug lag” where there is a time lag between approval for use of new drugs overseas and when it becomes available for patients in Japan, which in some cases are due to “laboratory automation lag.”

I think those ‘sealer’ and ‘peeler’ robots we saw earlier were manufactured overseas. The idea for those robots seems like something that small-scale factories in Osaka would come up with.

With Higashiosaka’s technical capabilities, they would be able to make those robots. But those manufacturers do not realize the large potential for this market, particularly at the global scale because this sector in Japan is quite small as compared with the car industry.

They can of course produce one if they have the go ahead, but it’s not like they can sell large numbers of them afterward. It would just end up being a one-of-a-kind robot.

When using a foreign manufactured device, it can be challenging because we have to figure out on our own how to integrate it into our system.

I guess there are a lot of device manufacturers. But you need to be able to link them together to advance automation.

We need to contact people in other countries if we have any questions, and that means there are inevitably delays in our current situation. There is also an issue of standards.

You are referring to a common protocol between different robots?

There is a wide variety of devices and robots, and also many labs working on their development. We need to acknowledge this diversity but work to establish standards that allow the smooth integration of all of these efforts.

Automation will lead to new biology

Do you engage in a lot of research collaborations?

Yes, I do. We did a survey [on automation] in one project, and we received a lot of feedback saying, “I know there is automation technology available, but I don’t know how to use them” or “I don’t understand the merits of automation.”

Yes, I can see how it could be difficult to envision.

So we asked about their scientific interests and the problems they had, to which we proposed effective automation solutions for. I used to work in a robotics lab and then went to the medical university as part of a collaboration between medicine and engineering, and I am now at a life science research center. So, I am hoping to be able to serve as a bridge between science and technology.

There is probably a lot of different things you can propose when you know both sides.

In the life sciences, technology is often used as a tool, so I generally talk frankly with the researchers about the assets available and what I know. But I also think there is another side to automation.

Another side?

For example, in biological experiments, you conduct your experiments by planning on what day to do this and what day to do that. But which day is a unit of time decided by humans.

I guess it is not something that directly concerns a cell. It could just be one step within a workflow, just to ensure that a task does not fall on a weekend.

Cells function in a way that if a certain gene is expressed, they advance to the next step regardless of whether this happens on a weekend. Cells also do not have a set of defined rules for this process, and many things unfold autonomously and spontaneously. This is likely their natural state.

And its humans who are trying to explain it on our terms.

It is conceivable that human intervention is actually producing results that differ from the natural state. I think it is possible that through automation or autonomy, experiments can be conducted in more natural conditions.

Automation is not just a way to increase productivity, but to generate a new interpretation of biology as well.

Postscript

Living organisms can adapt to many things, and likewise, cells used in experiments also adapt to the feed, like media and growth factors, given to them, which you could say is making them domesticated. It brings to mind a vague memory of being told in a physics class I took long ago that “observation itself is already an act of intervention.” Our talk made me ponder about how observation of nature should be carried out if human intervention is already considered disrupting natural states.